OEM 2/3 Flutes Carbide End Mill for Aluminum Processing Straight Shank Flat End mills

Even the processing of complex thin-walled cavity parts can be easily completed.( As shown in the following figure)

Application

Manufactured with utmost precision and quality, this product is specifically designed to handle aluminum alloys with ease. Whether you are working with lightweight aluminum or heavy-duty alloys, our machine guarantees efficient and precise processing every time. Say goodbye to manual labor and tedious processes – our aluminum alloy processing machine will accelerate your production and simplify your work.

Our aluminum alloy processing machine boasts numerous features that set it apart from others in the market. It is equipped with the latest cutting-edge technology, guaranteeing precise and consistent results. The machine is incredibly efficient, reducing production time and maximizing output. Its robust construction and durable components ensure a long-lasting performance, making it a reliable investment for your business.

Being sold directly by the manufacturer, we offer this exceptional product at a discounted price. No middlemen, no extra costs – just a straight deal from us to you. By purchasing directly from the manufacturer, you not only save money but also receive the assurance of supreme quality and top-notch customer service.

Specifications

Crafted from the finest UK10/UK20 raw material, this spiral tool boasts a striking silver appearance that exudes elegance and style. With a minimum outer diameter of 1 or 3 mm and a maximum of 20 mm, this spiral tool can tackle a wide range of machining tasks, making it a versatile addition to any workshop or production facility.

The total length of the tool reaches an impressive 100 or 150 millimeters, enabling users to handle even the most challenging projects with ease. The added convenience of choosing from 2 or 3 flutes further enhances the tool's versatility, allowing for efficient material removal and improved chip evacuation.

One of the standout features of our UK10/UK20 Silver Spiral Tool is the availability of two spiral angles - 45 degrees and 55 degrees. This gives users the flexibility to choose the ideal spiral angle based on their specific requirements, ensuring optimal performance and excellent results every time.

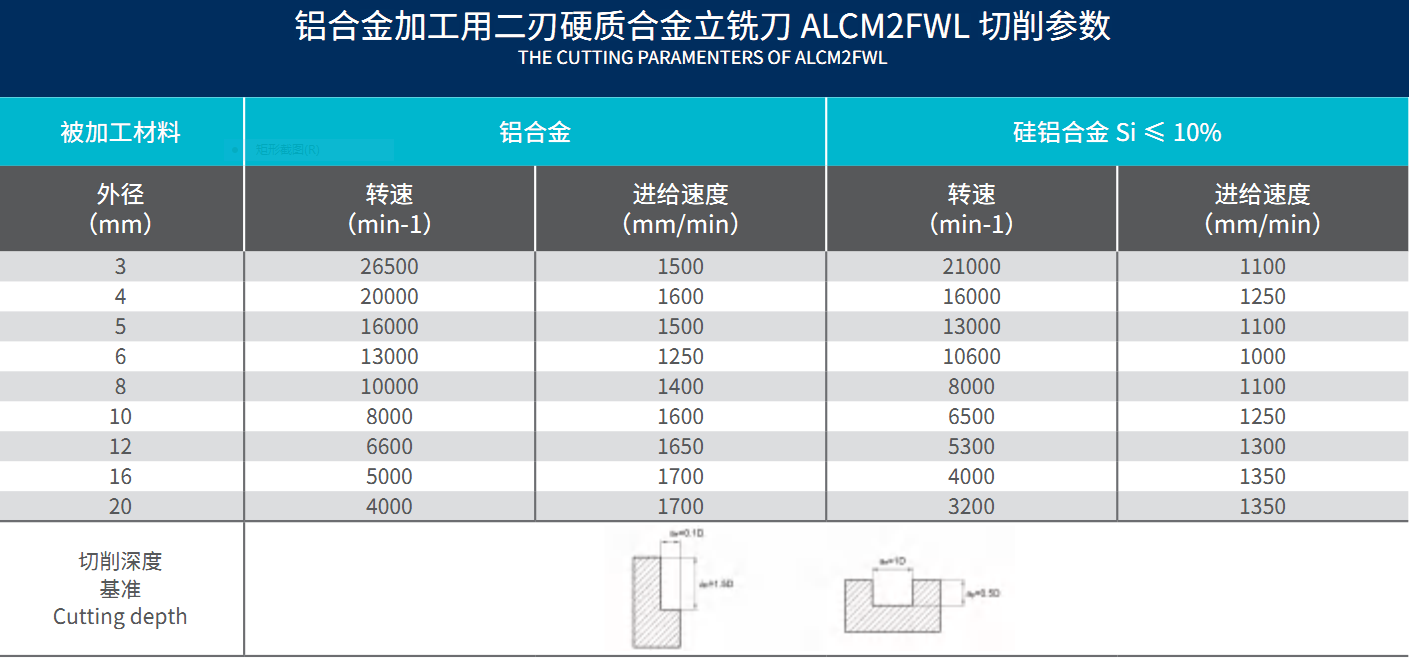

The cutting parameters of ALCM2FWL

1. This cutting condition is suitable for the special machine for high speed machining of aluminum alloy.

2. Please Use cutting fluid or strong air cooling to remove chips

3. Processing sparks and damage caused by the heat may cause combustion or fire , please pay attention to fire prevention

4. Operation balance must be tested before processing.