OEM 2/3/4 Flutes Ball Nose End mills with Straight Shank

4 Flutes Ball Nose End mills with Straight Shank

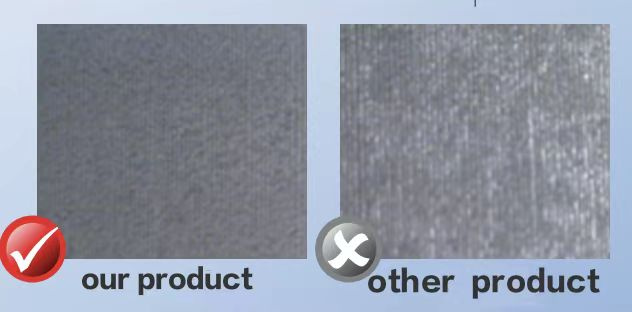

1. The center design of the ball edge that combines high strength and sharp edge can properly handle the chips generated during cutting processing.

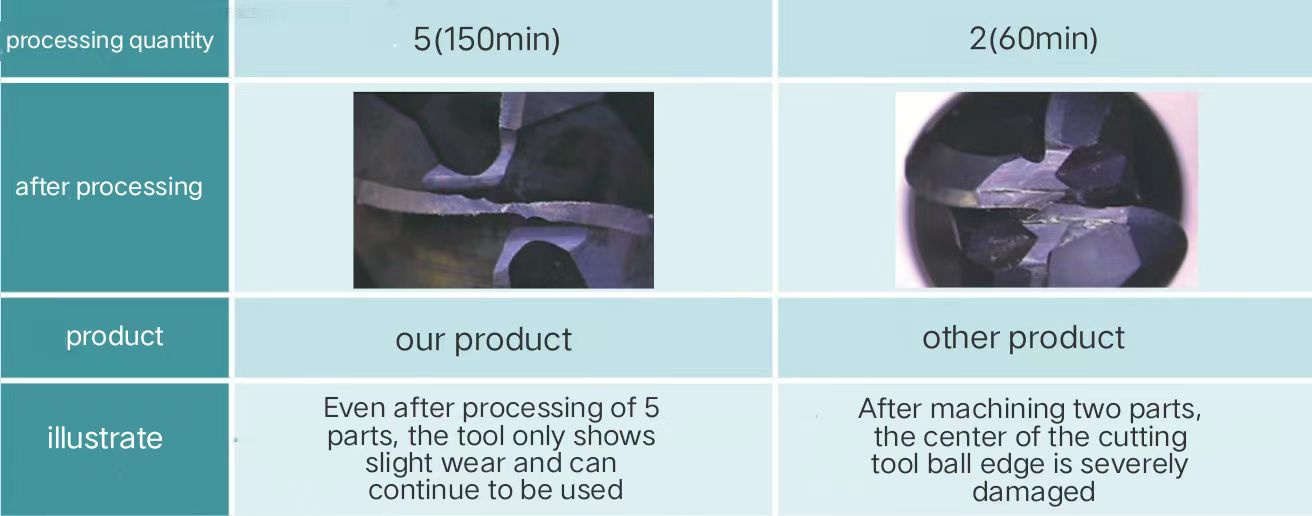

2. Application situation of high-performance four edge ball end milling cutter in milling Cr12(36HRC)

Application

2/4 edge straight shank ball end mills are suitable for profiling, cavity machining, and spherical machining. The 2 flutes is suitable for profile milling and high-speed machining with a wide range of applications. It is very suitable for processing carbon steel, alloy steel, prehardened steel, quenched steel(55HRC~68HRC), cast iron, and ductile iron, as well as stainless steel, Titanium alloys and heat-resistant alloys. As for the 4 flutes, it can achieve higher feed speed, thereby achieving higher cutting efficiency. It is very suitable for processing carbon steel, alloy steel, prehardened steel, quenched steel(55HRC~68HRC), cast iron, and ductile iron, as well as stainless steel, Titanium alloys and heat-resistant alloys.

Specifications

There are more than 20 models of the 2 flutes milling cutters to choose from, while there are more than ten specifications of the 4 flutes milling cutters. Their raw materials are all UK20 and TAN coatings.

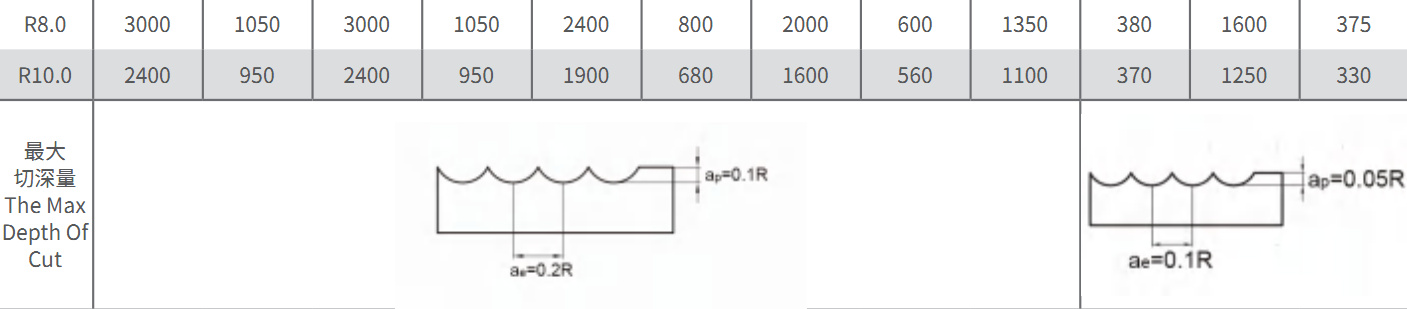

The cutting parameters of QCM2F/QCM4F

The cutting parameters of QCM2F

1. Please use high-precision machine tools and tool handles.

2. Please use air cooling or cutting fluid that is not prone to generating smoke.

3. When the installation rigidity of the machine tool work piece is poor, vibration and abnormal sound may occur. At this time, the speed and feed speed in the above table should be reduced year-on-year.

4. The suspension length of the cutter should be as short as possible.

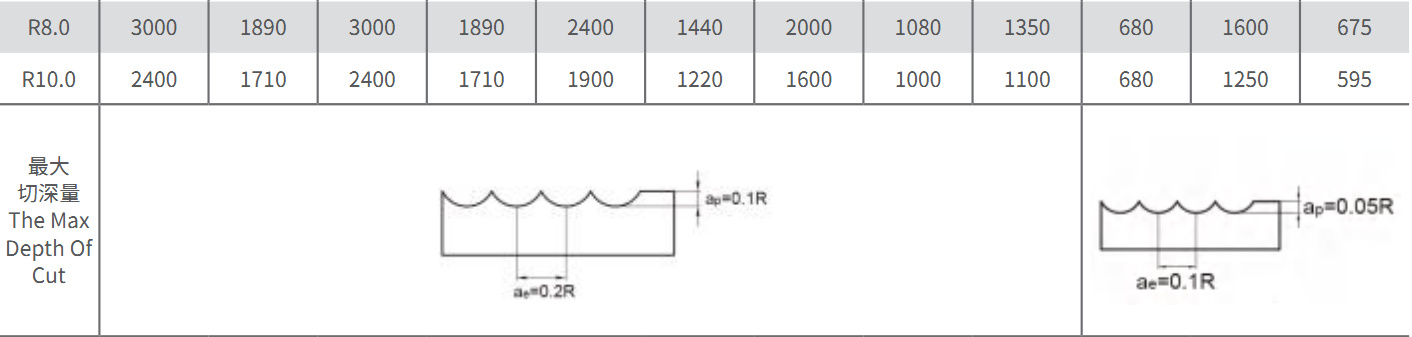

The cutting parameters of QCM4F

1. Please use high-precision machine tools and tool handles.

2. Please use air cooling or cutting fluid that is not prone to generating smoke.

3. When the installation rigidity of the machine tool work piece is poor, vibration and abnormal sound may occur. At this time, the speed and feed speed in the above table should be reduced year-on-year.

4. The suspension length of the cutter should be as short as possible.